Ithayela Installations And Refractory PRoducts

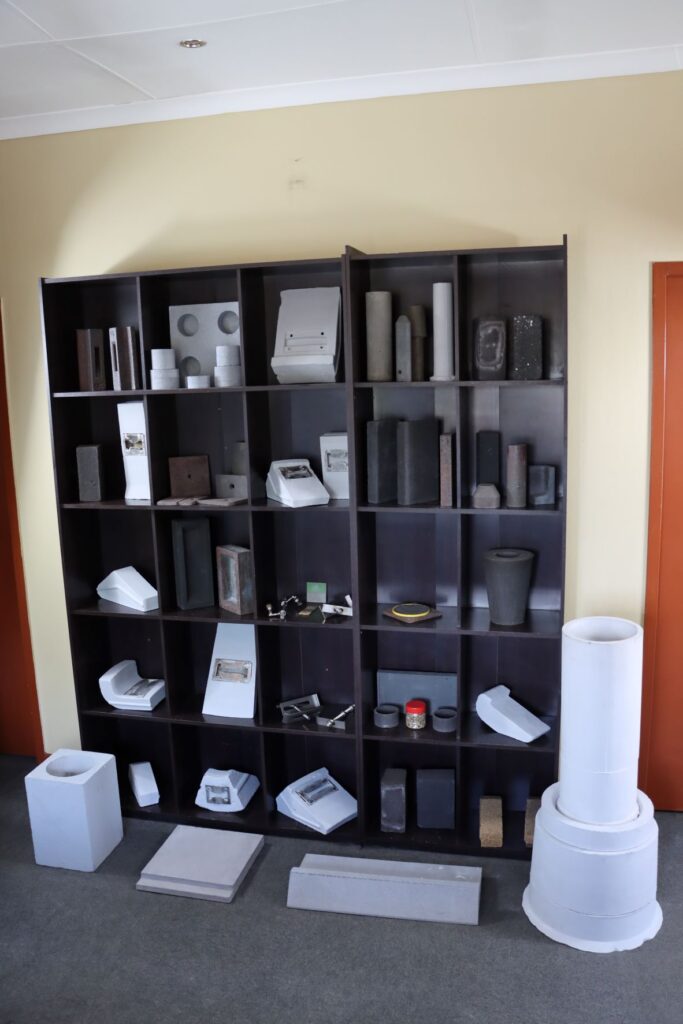

Products and area of specialization.

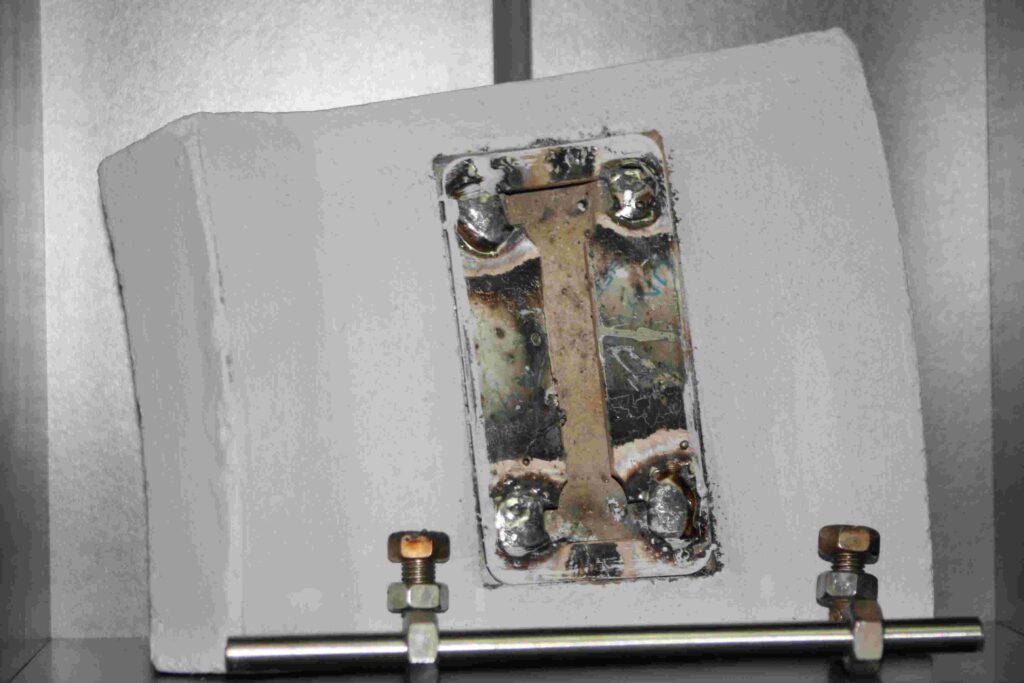

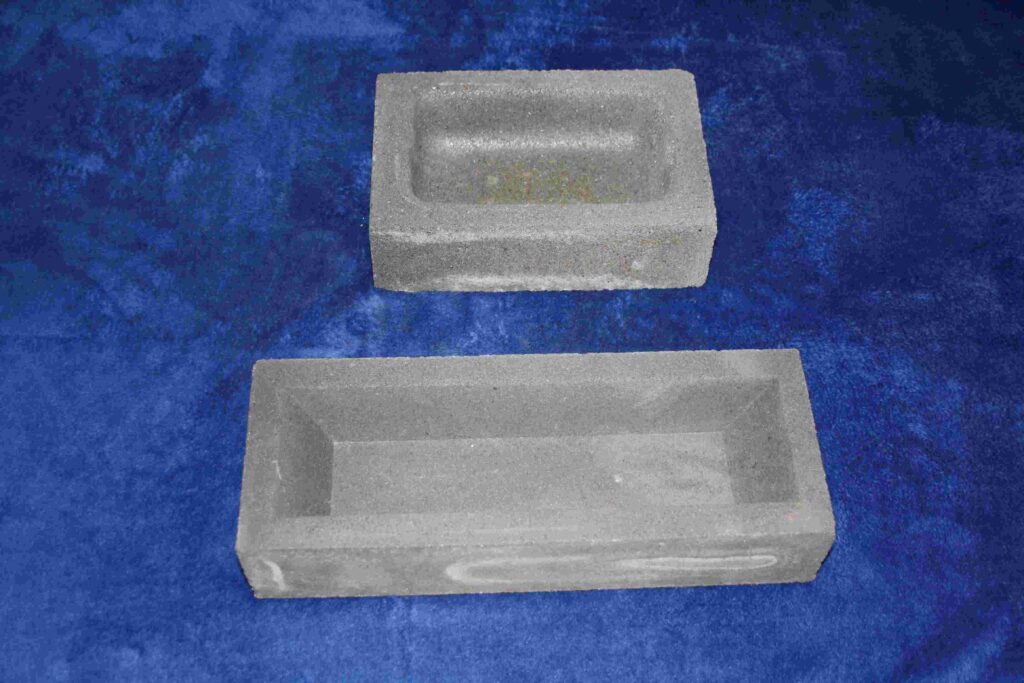

Ithayela Installations & Refractory projects area of specialization is Silicon Carbide Tile installation, mainly for Burner Mouth, Air Heater Sumps and Ducting in Coal fired Power Generation boilers, however we are able to install any refractory requirements. Our key customers are therefore ESKOM and Sasol. At these Power Generation Plants, Ithayela is also able to offer wear protection installation for burners, banjo boxes, P.FA and PA pipes.

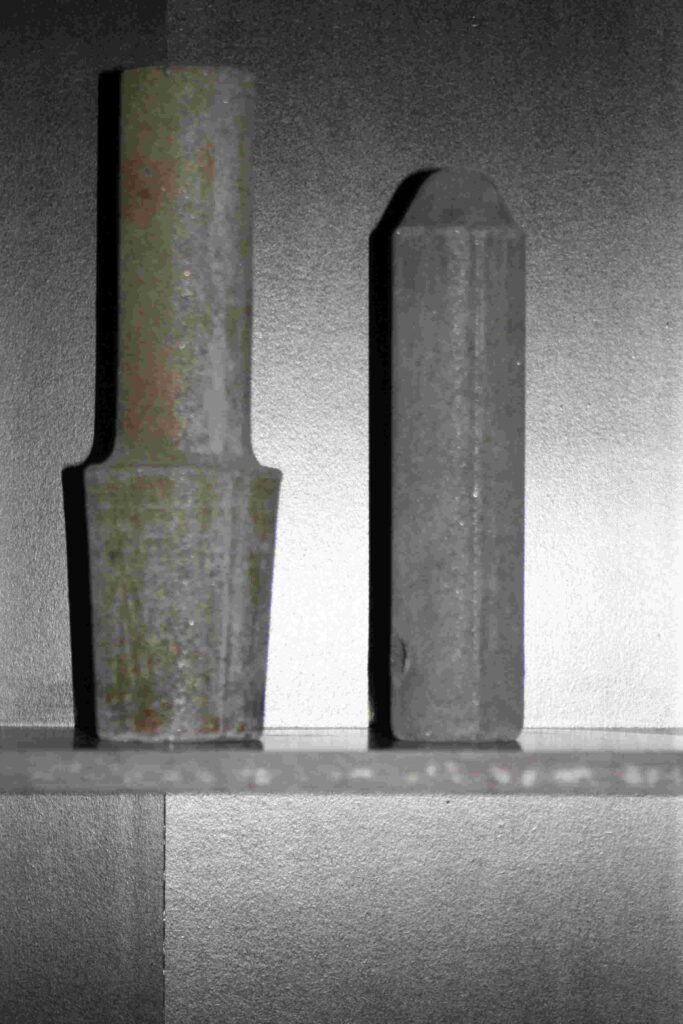

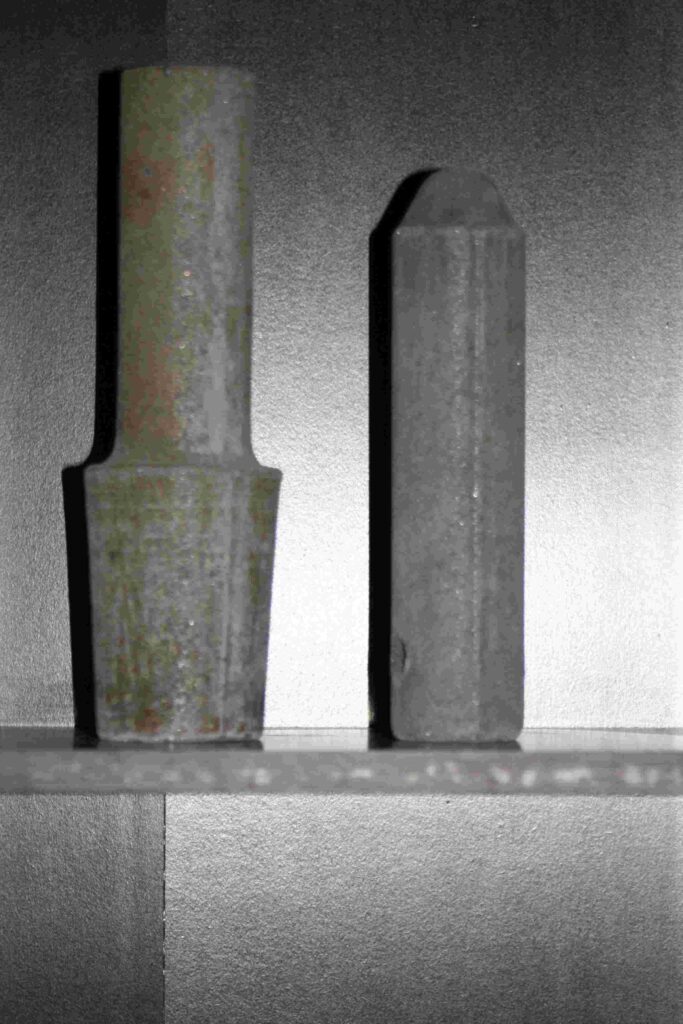

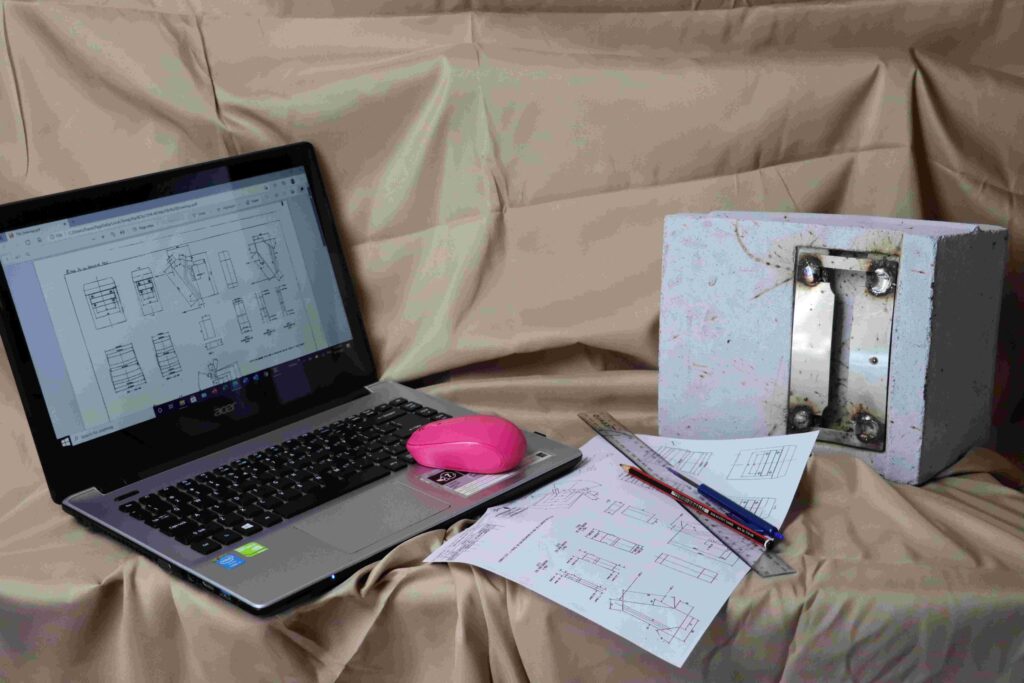

Ithayela Installations & Refractory projects has been installing Burner Quarl tiles in the Burner mouths at ESKOM Power Plants since 1979. Ithayela Installations and refractory Projects are able to carry out refractory installations in all areas of the Boiler and Kilns due to new expansion. We are now also able to offer a complete Kiln design and building service. Ithayela are able to offer the installation of "traditional" monolithic refractory installation by means ramming guniting.